Type in a search word

What are you looking for

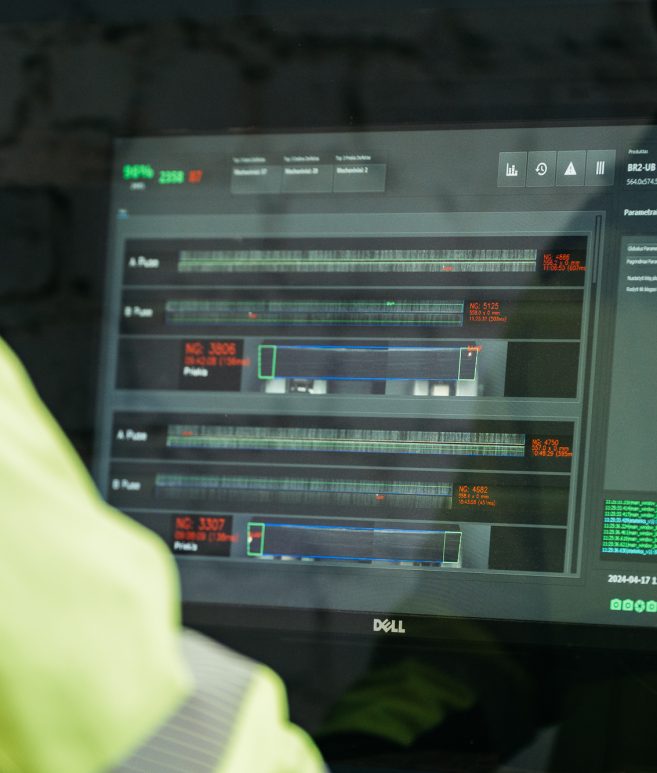

CUSTOM AI-POWERED AUTOMATED VISION INSPECTION AND QUALITY CONTROL FOR SURFACES, PRODUCTS, AND COMPONENTS

We create fully customized, high-speed vision systems for advanced industrial quality control. To elevate the inspection of your surfaces, edges, holes, products, and components to the next level, we use advanced cameras, optics, computers, and deep learning artificial intelligence (AI).

Our vision inspection and quality control systems can be integrated into your production lines to inspect semi-finished and fully-finished products without disrupting production processes or capabilities.

We integrate image-guided, automated vision inspection and quality control solutions into both low and high-speed, standard and non-standard production lines. Our vision inspection systems are adapted for use in a wide variety of industries for product quality control, sorting, and robot guidance.

VISION INSPECTION AND QUALITY CONTROL SOLUTIONS FOR RELIABLE PRODUCT QUALITY:

What Our Automated Vision Systems Do?

Each system is engineered specifically for each customer’s product, material, geometry, and process. Our solutions combine advanced machine vision, AI, and industrial automation to deliver reliable, high-performance quality control:

Why customers choose our vision inspection solutions?

-

We design, build, integrate, and support your solution — hardware, software, controls, and data — as one accountable partner.

-

20+ years of automation experience, 500+ projects delivered, and a team of 400+ experts across software, hardware, AI, controls, and mechanical engineering.

-

Certified partnerships with ABB and Beckhoff, in-house R&D and manufacturing, and rigorously tested European-grade components.

-

Our modular frameworks allow easy adaptation to new products, higher volumes, and evolving quality requirements.

-

Preventive and predictive maintenance, remote diagnostics, and fast-response service ensure your system remains reliable throughout its lifecycle.

We provide automated vision inspection and quality control solutions for various industries:

Wood and Furniture

Manufacturing

Automotive

Chemical

Machinery

Energy

Construction

Electronics

Logistics

Medical

Agricultural

Food and others