Type in a search word

What are you looking for

Industrial packaging solutions: FEFCO 410

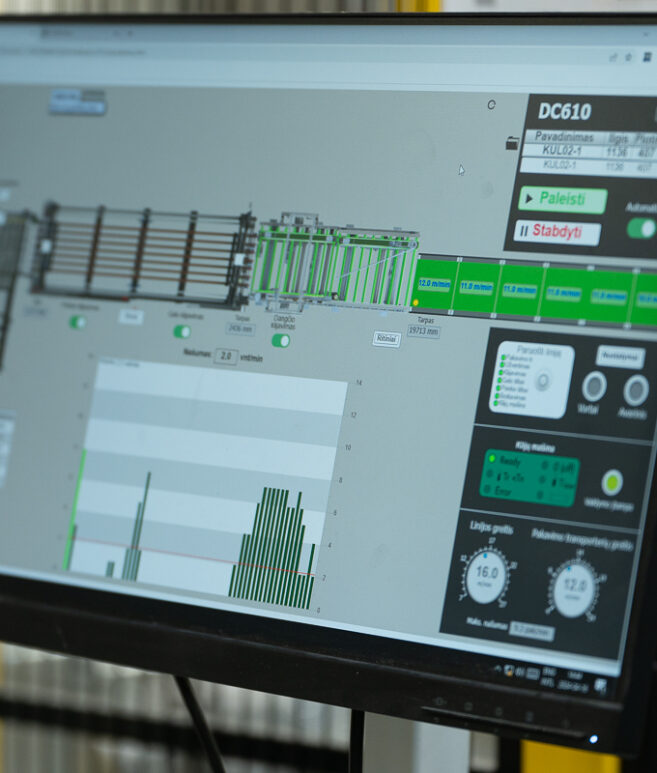

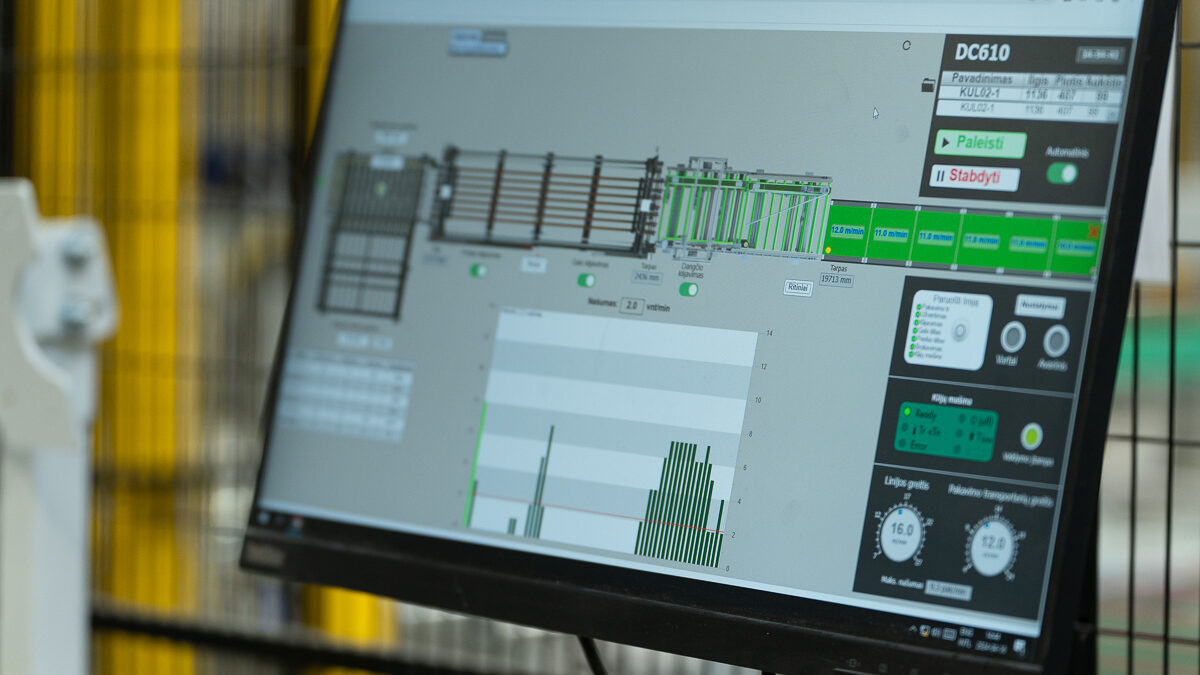

This project features a fully automated industrial packaging line designed for FEFCO 410 box forming, from initial formation to final gluing. At the push of a button, the system forms boxes in the selected format and transports them via a vacuum conveyor. Structural components such as partitions and honeycomb cores are inserted by two synchronized industrial robots, maintaining continuous production flow. The process concludes with automated hot glue sealing—both end and edge—without pausing the line. Operating at speeds up to 12 boxes per minute, the system requires only one operator for supervision.

Photos of the project:

Biggest challenges

Project in numbers

Operating Principle

01: BOX FORMING

Automated unit forms and transfers boxes based on the selected format.

• Upon a single press of a button, the selected box size is automatically formed.

• The formed box is conveyed to the assembly stage using a vacuum conveyor.

02: PARTS AND HONEYCOMB INSERTING

A robotic cell inserts structural elements (e.g., partitions, honeycomb cores) into the box without interrupting the production flow.

• Two synchronized industrial robots perform the loading process.

• A larger robot picks components from a stack and places them onto a positioning table.

• Equipment includes:

>> One main basing conveyor.

>> Two roller conveyors for supplying component stacks to the robot work zone.

>> One roller conveyor for removing empty pallets.

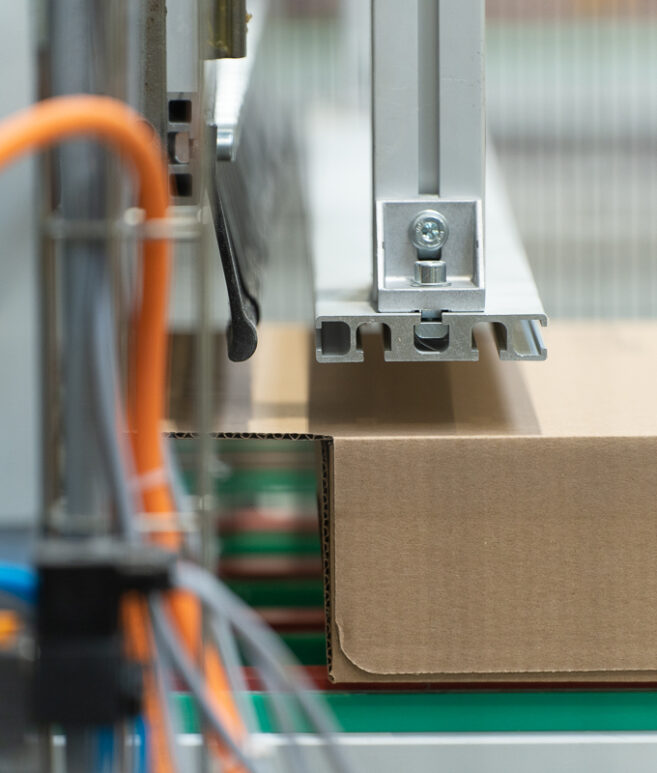

03: BOX GLUING WITH HOT GLUE

The gluing process is performed in two continuous steps:

• End sealing

• Edge sealing

The gluing is executed without stopping the line, ensuring optimal efficiency.