Synthesis between TECHNOLOGY & INNOVATION!

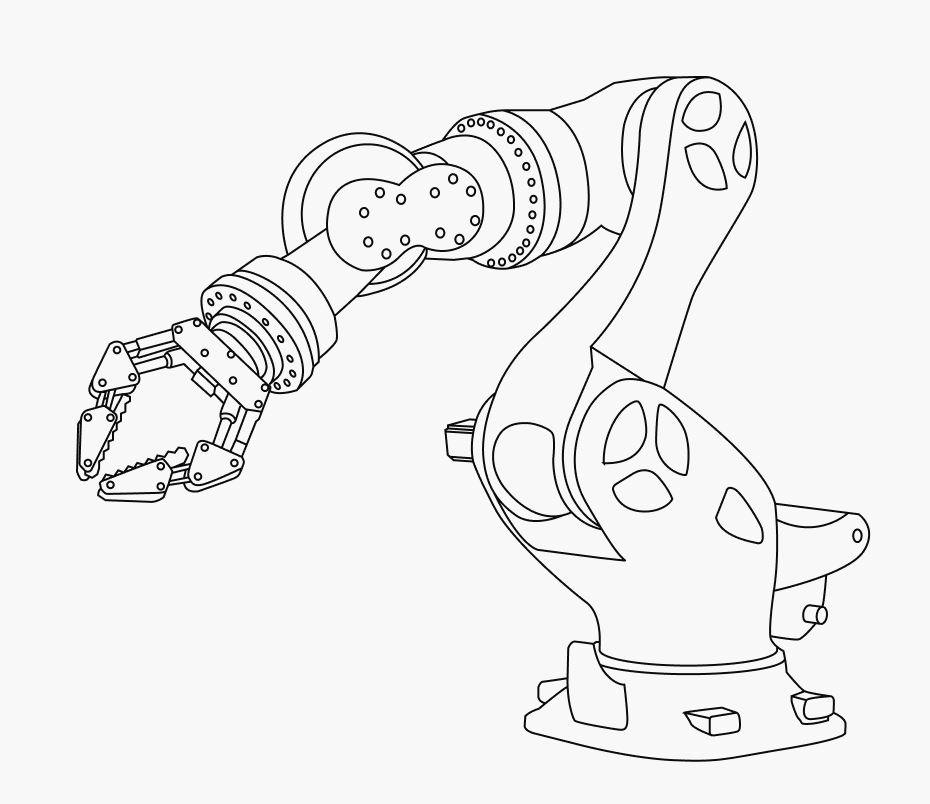

By implementing smart end-to-end factory automation solutions, we are ready to handle the full cycle of production process automation, robotization, and innovation projects.

What are you looking for

By implementing smart end-to-end factory automation solutions, we are ready to handle the full cycle of production process automation, robotization, and innovation projects.

By implementing smart end-to-end factory automation solutions, we are ready to handle the full cycle of production process automation, robotization, and innovation projects.

We specialize in the design and manufacturing of customized assembly and product handling automation systems, which we integrate in low and high-speed standard and non-standard production lines.

VMG TECHNICS specializes in developing innovative solutions for optimizing production processes, automation, robotization, and improving industrial performance. We advise on manufacturing process automation strategy and implementation of advanced technologies that drive production speed, flexibility, accuracy, and quality.

Automation with an all-inclusive service:

Custom robotics and automation

Technological line

Artificial intelligence

Human–machine interaction

Advanced engineering

Machine learning

Advanced analytics

Installation

Acceptance testing

On-site technical support

Preventative maintenance

Product quality management

Production flexibility and safety

Production process optimization

Industrial performance improvement

Proof of concept studies

Operational intelligence

Innovation management

Study center of competence

We provide regular equipment maintenance to prevent equipment failure and increase operational efficiency and extending the lifespan of production line equipment.

How we operate

With an advanced machinery infrastructure, our in-house team of professional can meet the most complex challenges of metal processing. Each order is produced according to the customer’s individual needs:

Engineering

Development

Project management

Supply chain management

Assembly and packing

3D measurement

Complex structures

CNC laser

CNC bending

Tube bending

Coil slitting line

Stamping

Deep drawing

Guillotine

Rolling

CNC miling

CNC turning

Miling

Turning

High-precision grinding

Drilling

Others

CNC plasma sheets

CNC plasma tubes

Band saw

Wet painting (6x6x18)

Shot blasting (6x6x15)

Powder coating

Welding

We offer a wide range of custom metal processing services – production of stamped and shaped metal parts. We create a range of metal components in all sizes and forms. After the metal parts are stamped, we have the capability to assemble and package the final product using our automated production line.

For production of stamped and shaped metal parts we can use:

Stainless steel

Low- and high-carbon steel

Aluminum

Galvanized material

Other metals

Stainless steel

Low- and high-carbon steel

Aluminum

Galvanized material

Other metals

We help to adapt to the industry 4.0 changes and be better equipped with an advanced machinery infrastructure. In our own innovation and R&D center we assess the production improvement opportunities. We analyze our client ideas from a technical, efficiency, innovation, and a commercial standpoint, conducting feasibility studies to integrate into the mass production processes and assembly lines.

Innovative technology and production process development center services:

Full cycle development services

Consulting

Development

Integration

Support & maintenance

Reengineering

Consulting

Strategy

Technology

Solution

R&D programs

Innovations in production automation and technologies

Study center of competence

Please contact us directly, our team reach out to you and develop a customized solution tailored specifically to your goals. Together, let’s elevate your projects to new heights by unleashing its full potential.

Pramonės st. 14, Dirvupiai, Klaipėda, Lithuania